In this blog, we’ll explore the role of dock levelers, their functionality, types, benefits, and the reasons why they are a must-have for any business dealing with containerized goods.

What is a Dock Leveler ?

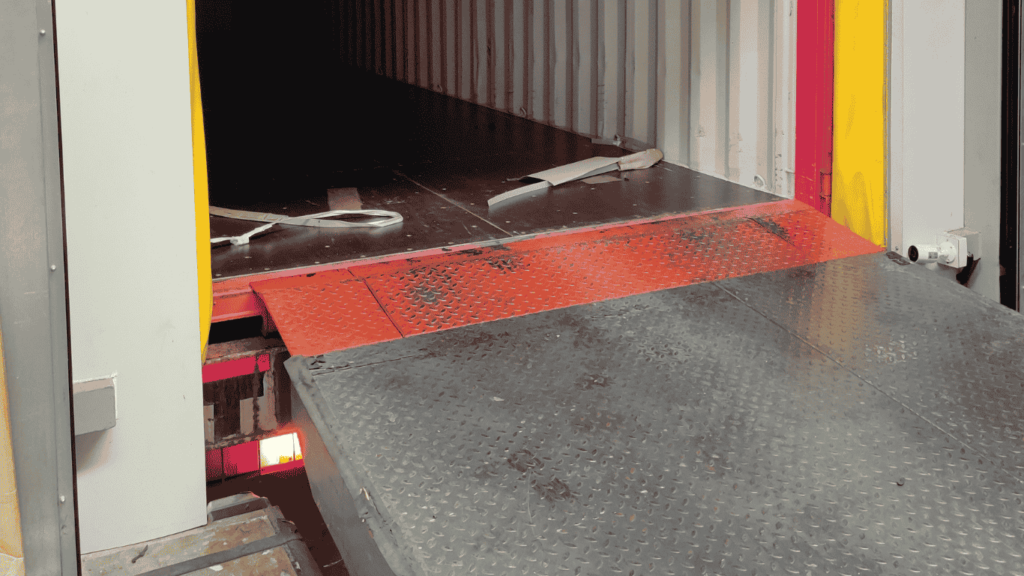

A dock leveler is a mechanical or hydraulic platform that bridges the gap between a loading dock and the container or truck bed. It allows for the seamless movement of goods between the two surfaces, compensating for height differences and providing a smooth, stable pathway for forklifts, pallet jacks, and manual loading equipment.

Dock levelers are a critical component in warehouse operations, enabling quick and efficient loading or unloading while maintaining safety and reducing the risk of damage to goods or equipment.

Why Are Dock Levelers Important for Containers?

Containers come in a variety of sizes, with varying floor heights depending on the vehicle or storage requirements. This height mismatch often leads to delays or unsafe practices during loading and unloading.

Dock levelers solve this problem by:

Bridging Height Differences

They adjust to the height of the container or truck bed, providing a level surface for easy movement.

Enhancing Safety

Uneven or improvised ramps can lead to accidents. Dock levelers create a stable and secure path, reducing the risk of injuries or falls.

Protecting Goods

Goods can be damaged due to abrupt height changes or unsteady platforms. Dock levelers ensure smooth transfers, minimizing damage.

Increasing Efficiency

By reducing manual adjustments and facilitating quick operations, dock levelers save time and labor costs.

Types of Dock Levelers for Container Loading

There are several types of dock levelers available, each designed for specific needs. Understanding these options can help businesses choose the right one for their operations.

Mechanical Dock Levelers

These are operated manually using a pull-chain system. They are cost-effective and durable, making them ideal for facilities with moderate loading needs.

Hydraulic Dock Levelers

Powered by hydraulic systems, these levelers offer automated operation and are suitable for high-volume facilities. They provide superior precision and safety.

Air-Powered Dock Levelers

These levelers use an air-powered system to adjust the platform. They are low-maintenance and environmentally friendly.

Edge-of-Dock Levelers

Mounted on the edge of the dock, these are compact solutions for facilities with limited space.

Vertical Dock Levelers

Designed to remain upright when not in use, these levelers are ideal for temperature-controlled environments as they help maintain a sealed dock door.

Benefits of Dock Levelers in Container Loading Operations

Time-Saving

By providing a quick and efficient way to load and unload, dock levelers reduce downtime and improve overall productivity.

Cost-Efficiency

Reducing the time and labor involved in manual adjustments translates to lower operational costs.

Enhanced Safety

Dock levelers prevent accidents caused by uneven surfaces or improvised ramps, creating a safer working environment.

Durability

Designed to withstand heavy loads and frequent use, dock levelers are a long-term investment.

Versatility

Suitable for a variety of container sizes and vehicle heights, dock levelers can accommodate diverse loading requirements.

Damage Reduction

The smooth transition provided by dock levelers prevents goods from toppling or getting damaged during transfer.

Key Features to Consider When Choosing a Dock Leveler

Load Capacity

The leveler should be capable of handling the weight of goods, equipment, and vehicles used in the operation.

Platform Size

The size of the dock leveler should align with the dimensions of the containers and vehicles.

Operational Mechanism

Depending on the volume of operations, businesses can choose between manual, hydraulic, or air-powered systems.

Durability and Build Material

High-quality steel or aluminum construction ensures longevity and resistance to wear and tear.

Safety Features

Look for levelers with safety lips, anti-slip surfaces, and secure locking mechanisms.

Ease of Maintenance

Opt for levelers that require minimal upkeep to save on maintenance costs and downtime.

Best Practices for Using Dock Levelers with Containers

Regular Inspections

Ensure the dock leveler is in good condition before use to prevent accidents or delays.

Load Distribution

Distribute weight evenly to avoid overloading and potential damage to the leveler.

Safety Checks

Verify that all safety features are functional and secure the leveler properly before loading.

Training Employees

Provide adequate training to employees on the proper use of dock levelers to enhance efficiency and safety.

Routine Maintenance

Schedule regular maintenance to keep the dock leveler in optimal working condition.

Real-Life Applications of Dock Levelers in Container Loading

Warehouses

Dock levelers streamline the transfer of goods in warehouses, improving logistics efficiency.

Manufacturing Facilities

They facilitate the movement of raw materials and finished goods, ensuring smooth production workflows.

Retail Distribution Centers

Quick loading and unloading help meet tight delivery schedules in retail operations.

Cold Storage Units

Vertical dock levelers help maintain temperature control, preserving the quality of perishable goods.

Ports and Shipping Terminals

Dock levelers are crucial in handling containers of varying sizes at high-traffic shipping facilities.

Challenges and Solutions in Using Dock Levelers for Containers

Challenge: Varying Container Heights

Solution: Invest in hydraulic or air-powered levelers that offer a wide range of height adjustments.

Challenge: Heavy Loads

Solution: Use high-capacity dock levelers designed for industrial applications.

Challenge: Limited Dock Space

Solution: Opt for edge-of-dock or compact dock levelers that save space without compromising functionality.

Challenge: Maintenance Downtime

Solution: Implement preventive maintenance schedules and choose low-maintenance models.

Conclusion

Dock levelers are indispensable in container loading operations, offering a seamless, safe, and efficient solution for bridging the gap between dock floors and container beds. Their versatility, coupled with features that enhance productivity and safety, makes them a valuable asset for warehouses, distribution centers, and manufacturing units.

By investing in the right dock leveler and adhering to best practices, businesses can optimize their loading operations, reduce costs, and ensure the safety of both goods and personnel.

For businesses aiming to stay competitive in today’s fast-paced logistics landscape, dock levelers are not just an option—they’re a necessity.

At Amvel Automation, we understand the critical role dock levelers play in streamlining container loading operations. Amvel Automation is a leading dock leveler manufacturer in India. These innovative solutions enhance productivity, ensure safety, and provide the versatility needed to handle diverse operational challenges. Whether you need to bridge height differences, protect goods during transit, or optimize your warehouse workflow, our range of high-quality dock levelers is designed to meet your specific needs.

By choosing Amvel Automation, you’re not just investing in a product but in a long-term solution tailored to elevate your logistics operations.

Let us help you achieve efficiency, safety, and reliability in every container loading process.

Contact us today how our dock levelers can transform your business operations.

Sales Co-ordinator

amvelinfo@gmail.com

+91 63808 99108

+91 79041 71723